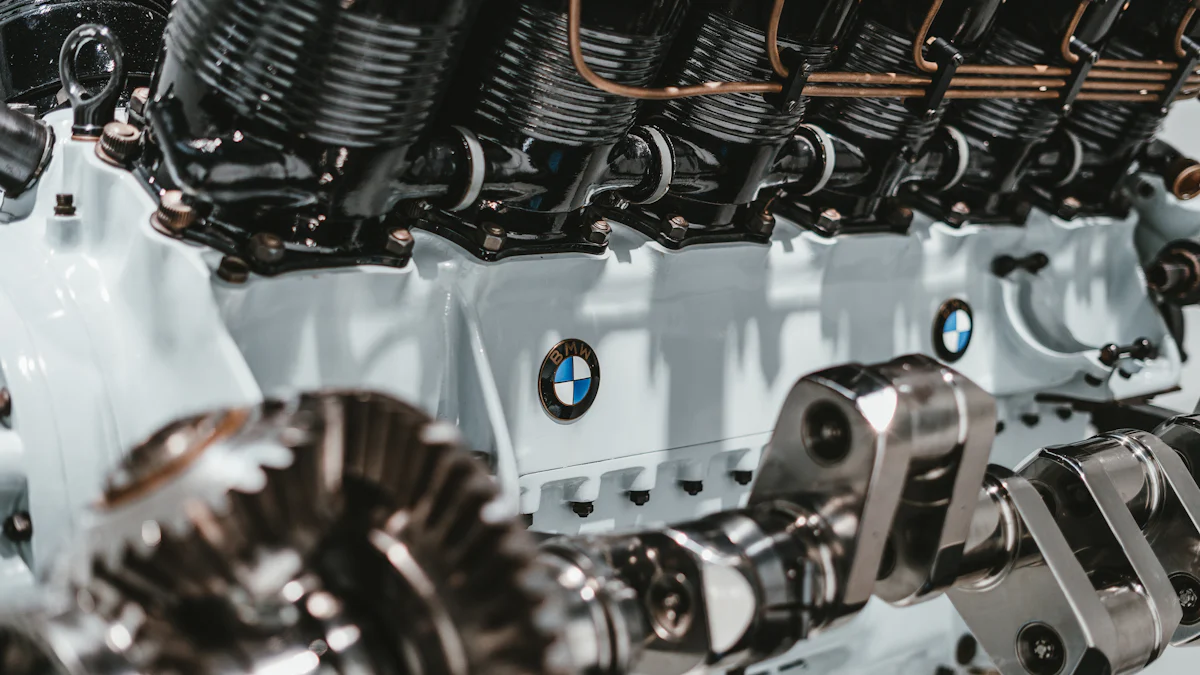

The N54 intake manifold engine stands as a pinnacle in the automotive realm, boasting accolades like six consecutive International Engine of the Year awards. Recognized for its exceptional performance, the N54 engine delivers peak power and torque ratings of 302hp at 5,800 rpm and 295lb-ft of torque. Upgrading the Exhaust Intake Manifold on this powerhouse can unlock even greater potential, enhancing both peak power and efficiency. This guide delves into the intricacies of this upgrade, offering a comprehensive walkthrough for enthusiasts seeking to elevate their driving experience.

Understanding the N54 Engine

When delving into the Engine Specifications of the N54 powerhouse, enthusiasts are met with a marvel of engineering. With a displacement of 2,979 cc, this engine has garnered numerous accolades, including six consecutive International Engine of the Year awards. Despite its acclaim, the N54 engine is not without its Common Issues and Limitations.

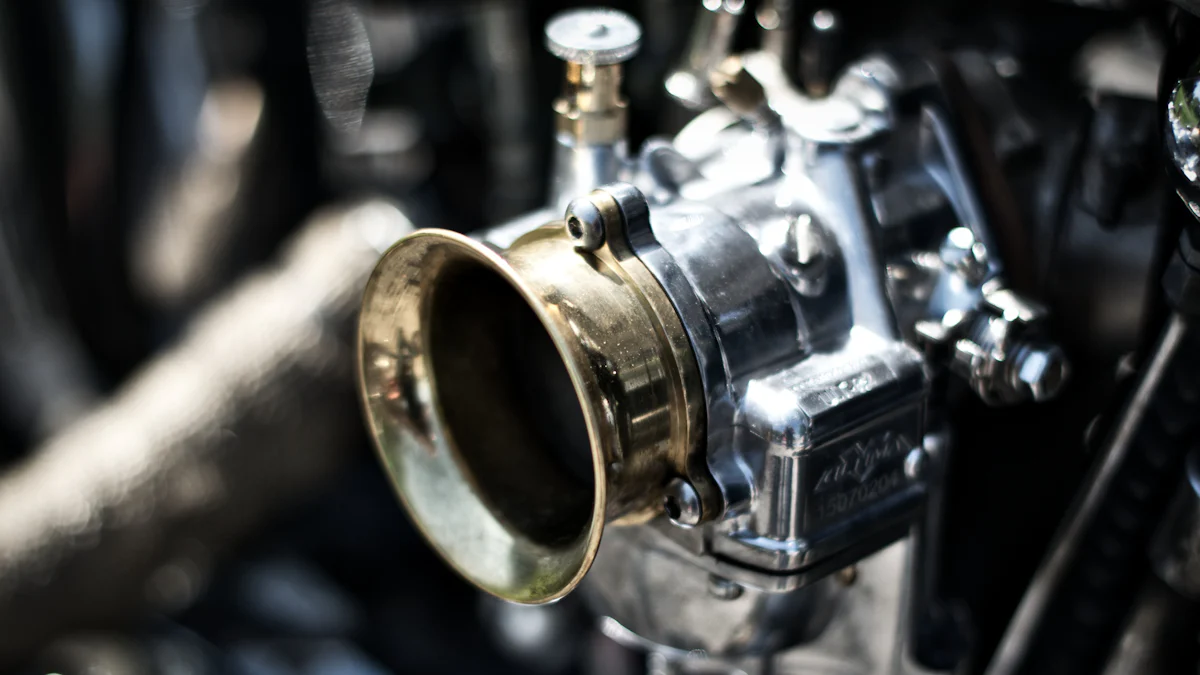

The allure of upgrading the Exhaust Intake Manifold on this iconic engine lies in its ability to unleash untapped potential. By enhancing both peak power and efficiency, this upgrade offers enthusiasts a gateway to heightened performance capabilities.

Preparing for the Upgrade

Tools and Materials Needed

Essential Tools

- Wrench set for various bolt sizes

- Socket wrench with extension bars

- Torque wrench for precise tightening

- Screwdriver set with flathead and Phillips head options

Recommended Materials

- High-quality gasket sealant for a secure fit

- Intake cleaning solution to remove residue effectively

- Replacement intake manifold gaskets for a complete seal

Safety Precautions

Personal Safety

- Wear protective gloves to prevent injuries from sharp edges or hot components.

- Use safety goggles to shield your eyes from debris or harmful substances.

Vehicle Safety

- Ensure the vehicle is parked on a level surface before starting work.

- Disconnect the battery to avoid electrical mishaps during the upgrade process.

Step-by-Step Installation Guide

Removing the Old Intake Manifold

Disconnecting Battery and Electrical Components

- Begin by disconnecting the battery to ensure safety during the removal process.

- Use appropriate tools to disconnect any electrical components attached to the old intake manifold.

- Securely store disconnected components in a safe location to prevent damage.

Detaching the Old Manifold

- Loosen and remove all bolts securing the old intake manifold in place.

- Carefully detach the old manifold from its position, ensuring no wires or hoses are still connected.

- Gently lift and remove the old intake manifold, keeping it aside for inspection.

Installing the New Intake Manifold

Positioning the New Manifold

- Clean the engine surface thoroughly to ensure a smooth fit for the new intake manifold.

- Carefully position the new manifold in place, aligning it with mounting holes on the engine block.

- Double-check alignment and make any necessary adjustments before proceeding.

Securing and Connecting Components

- Gradually tighten bolts starting from one end of the manifold to ensure even pressure distribution.

- Reconnect all electrical components and hoses to their respective connections on the new intake manifold.

- Use a torque wrench to secure bolts according to manufacturer specifications for a proper seal.

Post-Installation Checks

Inspecting for Leaks

- Conduct a visual inspection around all connection points for any signs of leaks or loose fittings.

- Start the engine and monitor closely for any unusual sounds or smells that may indicate leaks.

- Address any leaks immediately by tightening connections or replacing faulty gaskets.

Ensuring Proper Fitment

- Verify that all components are securely fastened and aligned correctly after installation.

- Perform a test drive to assess performance and check for any vibrations or irregularities.

- Consult with a professional tuner if necessary to optimize performance post-installation.

Tuning and Calibration

Initial Setup

Basic Tuning Parameters

- Tuning an engine involves adjusting various parameters to optimize performance.

- Key parameters for tuning include fuel delivery, ignition timing, and boost control.

- Understanding these parameters is crucial for achieving desired power and efficiency levels.

- Ignition timing tables dictate when the spark plug fires, influencing engine performance.

- Fuel scalar tables control the amount of fuel injected into the cylinders during combustion.

Software and Tools Required

- Utilize specialized software like COBB Tuning or Accesstuner for precise tuning adjustments.

- These programs allow access to the DME (Digital Motor Electronics) to modify critical engine settings.

- Boost control tables in the software enable adjustments to turbocharger spool mode and boost error correction.

- Accessing main fuel tables helps fine-tune the air-fuel ratio for optimal combustion efficiency.

Fine-Tuning for Optimal Performance

Adjusting Air-Fuel Ratios

- Achieving the ideal air-fuel ratio is essential for maximizing power output while maintaining engine health.

- Fine-tune fuel delivery using requested torque values to match engine load demands accurately.

- Monitoring RPM levels during acceleration aids in adjusting fuel injection rates for optimal performance.

Monitoring Engine Performance

- Regularly monitor requested torque values to ensure consistent power delivery across different driving conditions.

- Analyzing ignition timing tables allows for adjustments that optimize torque output at specific RPM ranges.

- Requested torque monitoring provides real-time feedback on engine response, aiding in immediate tuning corrections.

Recapping the meticulous steps undertaken unveils a path to heightened performance on the N54 engine. The upgrade to the intake manifold not only enhances power but also refines efficiency, aligning with enthusiasts’ pursuit of automotive excellence. Embracing regular maintenance rituals post-upgrade ensures sustained peak performance. Further tuning endeavors promise a journey towards optimal power delivery and precision in every drive.

Post time: Jun-26-2024